Sea-Help, as the leading breakdown service for skippers throughout Europe, analysed the individual cases and found what they were looking for: Incorrect storage of fuel in the ship’s tank during the time when the boats are not in use, in combination with moisture, heat and condensation, can cause the fuel to “tip over”. Clogged fuel filters are then the least of the evils, capital engine damage or an accident of the ship without drive with far-reaching consequences can be the result of a lack of care in tank maintenance.

The fact that the problem has become more pronounced in recent years, particularly with diesel, is to be found in the EN 590 fuel standard applicable to diesel fuels, according to which up to 7% biodiesel can be blended with the original mineral diesel fuel. Although the use of this product, which is mentioned at B 7 filling stations, reduces some of the emissions compared to mineral oil-based diesel (over the product life cycle, editor’s note), it has considerable disadvantages for all seasonally used vehicles such as pleasure boats, sailing boats, yachts, mobile homes and, for example, agricultural machinery: the durability of the fuel is limited by the use of biodiesel components. What normally does not occur in trucks and cars when used regularly can quickly become a problem for seasonally used vehicles. Heat exposure, as is common in southern countries, the formation of condensation in the vehicle tank and petrol station operators who are not quite so particular about the cleanliness of their tanks promote the growth of microorganisms in the fuel tank until their slimy, partially hardened substance clogs the filters and attacks the inner walls of the tank and the fuel lines.

The most widespread is the so-called diesel plague. Microorganisms such as moulds, bacteria or yeasts often infest diesel as early as in the supply chain from the refinery to the vehicle tank and are temperature resistant: they can grow to minus 18 degrees and well above 70 degrees. However, they need food to grow. Since diesel is allowed to contain up to 200 milligrams of water per kilogram of fuel according to DIN EN 590, the basic requirement for the microorganisms is initially covered. However, an absolute “treat” for the little pests in the fuel has proved to be the organic content in the diesel, which has now been increased to 7% and which promotes growth excessively.

What few people know is that pure biodiesel may contain up to 500 milligrams of water per kilogram of diesel, but can bind up to 5000 milligrams of water. However, if biodiesel is mixed with mineral diesel, the mixture gradually releases the water. Since mineral diesel acts on the water like an emulsifier, the fine droplets are distributed in the fuel and lose the ability to sink to the bottom of the tank where they can be drained. For our diesel plague microbes, this means that food is sufficiently available in the entire fuel and not just in the water layer at the bottom of the tank. If the owner nevertheless finds water at the bottom of the tank that he can drain, the problem is not solved: it simply means that the fuel is already highly supersaturated with water.

If heat and possibly further condensation water is added in this situation, a real “comfort zone” is created for the organisms in the diesel tank in which they can spread out magnificently, with fatal consequences: The lubricating capacity of the diesel sinks, bio-sludge clogs filters, pipes and injection pumps and the hydrogen sulphide produced by the bacteria’s metabolism can permanently damage even the walls of solid tanks. On the other hand, during the months when no fuel is used and no fuel can be replaced by refuelling, only the use of a biocide, as contained in modern additives, helps to contain the growth of microbes.

Another form of infestation is the formation of polymers through oxidative aging. For those of you whose last hour of chemistry was a little while ago: Long-term exposure to heat and air in the diesel tank changes the structure of the fuel. This process is roughly comparable to caramelizing sugar in a hot pan and that actually describes it best, even if chemists among the readers are now balking at the hairs on the back of their necks. Large, sticky excretions form at points up to the palm of the hand, which in the final stage take on a partially black colour, settle on the tank walls or eventually sink to the bottom. They feel like tree resin and are ideal for sealing pipes and filters.

Of course, these dangers are well known to mineral oil producers. That is why some use additives in diesel to make it more durable. However, they assume “normal” use: The diesel is transported from the refinery to the filling station, finds its way into the vehicle tank and is used up within two to three weeks. No mineral oil manufacturer can produce fuels, let alone diesel with a bio component, with a shelf life of up to two years, which retain their quality even in a small, often moist tank under sometimes extreme external heat conditions. The owners of the boats must take the appropriate precautions themselves. And that is easier than thought, by increasing the additive content in the diesel to make it more durable.

However, dangers do not only lurk in the diesel, gasoline tanks of gasoline engines can also be the cause of engine failure. According to Sea-Help, water in gasoline is the cause in most cases, but it is possible to protect yourself at least in part against it. However, if the skipper has hit a petrol station that puts water in the tank instead of petrol, no chemicals will help. This can often happen in southern countries: Large tanks at the filling stations and low petrol turnover are the reason for the fact that over time the 100 milligrams of water per kilogram of petrol allowed by the DIN standard will segregate. Since water is heavier than petrol, it settles on the bottom of the tank and is sucked in by the petrol pump at the filling station and transported into the boat tank. There is an effective remedy for this: skippers should only select filling stations that are frequented frequently or fill up at car filling stations with canisters.

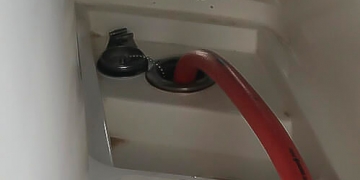

In most cases, however, the cause of water in the fuel tank lies with the skippers themselves, even if it is difficult to see at first glance. The main cause is condensation water, which mainly forms on the inner walls of the tank during winter storage and dissolves in the fuel. The moisture in addition gets into the tank via the tank ventilation. Sea-Help employees have recently been able to identify an increasing number of defective, not properly closing tank caps or sealing rings on the filler necks as the cause of water ingress. These tiny amounts of water are particularly treacherous because the owner only notices them when it’s too late: excessive wear on engine components that come into contact with fuel or rust usually result in high workshop bills.

Plain text:

- The so-called “diesel plague” can affect any diesel tank in which diesel fuel is stored for more than six months.

- Effects of diesel pollution: formation of residues that clog the fuel filter (engine failure) and drastic reduction in the lubricity of the fuel (damage to engine components lubricated by fuel)

- prevention in case of infestation: professional tank cleaning and later addition of biocide-containing additives during each filling process

- prevention: Addition of biocide-containing additive at each filling operation

- Attention: Avoid overdose in any case. Furthermore, under certain circumstances, additives can change the fuel properties and lead to the engine warranty becoming void. Please always consult the engine manufacturer before use.

Step by step to a clean tank:

This work was carried out in Croatia at the end of May 2018.

1. emptying of the entire tank filling:

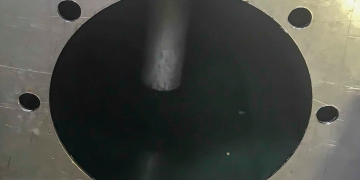

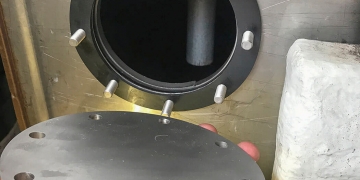

2. installation of a service hatch:

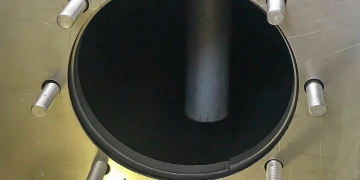

3. cleaning of the tank:

4. cleaned tank, completion of the service hatch for future cleaning operations:

The total costs for cleaning and the installation of two service hatches were 756,- Euro.

We would be pleased to make you an individual offer for this service. For enquiries, please contact tankcheck@sea-help.eu